Sorry for English, i cannot write German.... I understand it (kinda) so feel free to respond in German

When i started flying (many years back ) i bought a Robbe projeti after a few years. I really love the plane and stil have it (a bit damaged but still in 1 piece). Since i started flying turbine jets i have always dreamed of having a big projeti with a turbine engine. A few years back i found the gonzales project and found what i was looking for.... almost. I would really love a gfk fuselage and a jet for larger engines. Last year in Model city (http://www.modelcity.info/) i met a member of the gonzales team and i was hooked. When i got home i started my project the next day (June 2015) and now it looks like a plane

) i bought a Robbe projeti after a few years. I really love the plane and stil have it (a bit damaged but still in 1 piece). Since i started flying turbine jets i have always dreamed of having a big projeti with a turbine engine. A few years back i found the gonzales project and found what i was looking for.... almost. I would really love a gfk fuselage and a jet for larger engines. Last year in Model city (http://www.modelcity.info/) i met a member of the gonzales team and i was hooked. When i got home i started my project the next day (June 2015) and now it looks like a plane  Still needs a lot of work....

Still needs a lot of work....

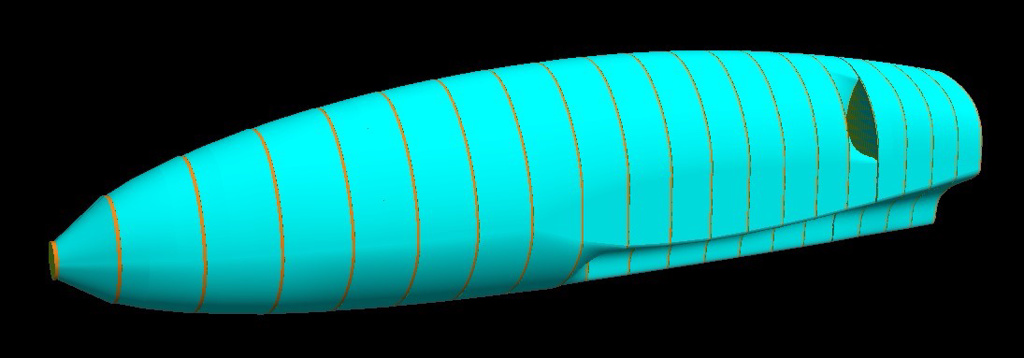

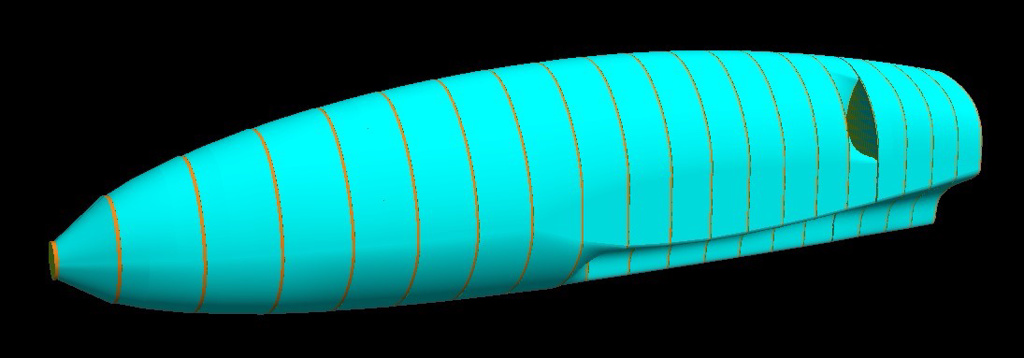

I started with DevFuse to draw the fuselage. I used side and top views from the original projeti.

After cutting the foam layers of the fuselage and wing cores it looked like this:

The gonzales team had issues with the CG because of the short fuselage and the swept-back wings. I am creating a longer fuselage by moving the wings back. The first position was a bit weird end i ended up with a position that looked nice.

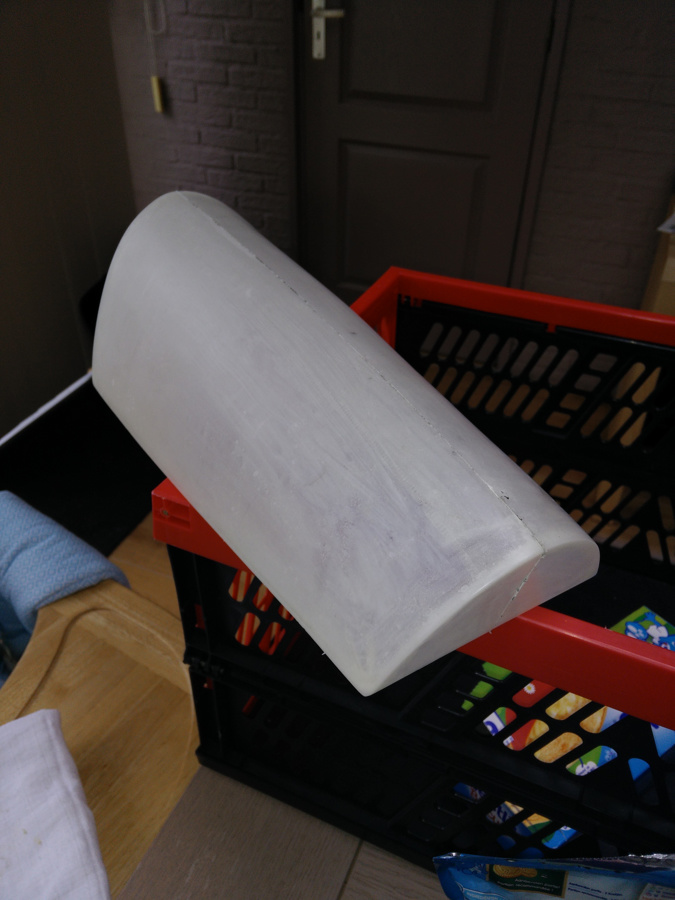

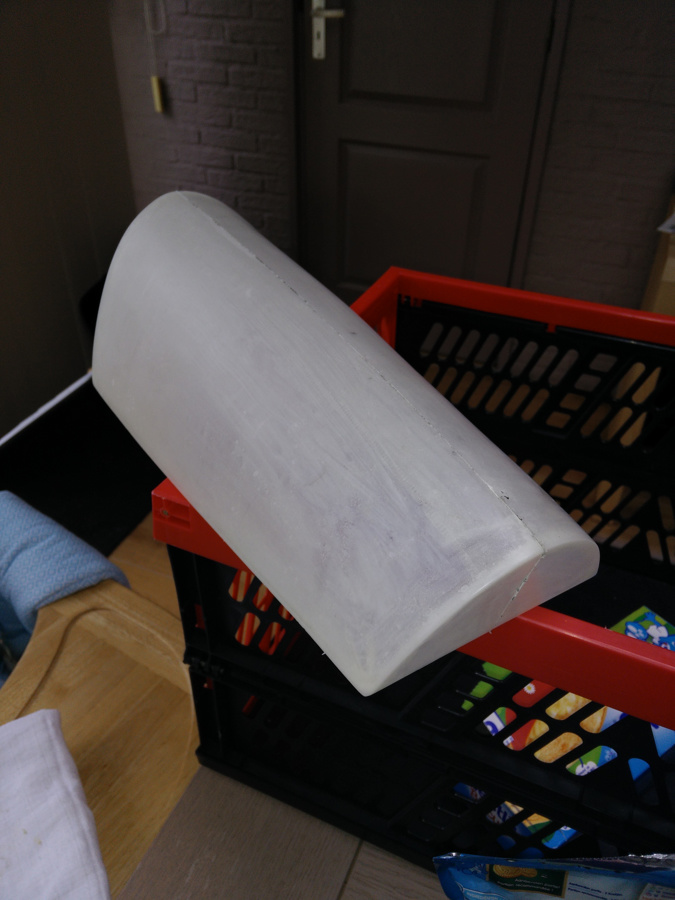

The fuselage looks nice and slim but is a lot wider then the projeti. It needs to be 170mm wide to accommodate a large engine. I want a simple P80 to fit but also a larger engine up to 18kg First gfk part was also created

First gfk part was also created

Wings are made from a styrofoam core with 110g glass fiber cloth and 1.5mm balsa. This makes a very strong wing. A bit heavy but remember the 18kg turbine? It needs to be strong It is only a 2m wingspan.... I had a alu tube lying around from a acrobatic plane and used that with newly created gfk tubes. I used the tube as a drill also.

It is only a 2m wingspan.... I had a alu tube lying around from a acrobatic plane and used that with newly created gfk tubes. I used the tube as a drill also.

The fuselage is about 120cm long and weights 950g from the mold. A bit heavy but also very strong.

All put together it looks awesome

When i started flying (many years back

) i bought a Robbe projeti after a few years. I really love the plane and stil have it (a bit damaged but still in 1 piece). Since i started flying turbine jets i have always dreamed of having a big projeti with a turbine engine. A few years back i found the gonzales project and found what i was looking for.... almost. I would really love a gfk fuselage and a jet for larger engines. Last year in Model city (http://www.modelcity.info/) i met a member of the gonzales team and i was hooked. When i got home i started my project the next day (June 2015) and now it looks like a plane

) i bought a Robbe projeti after a few years. I really love the plane and stil have it (a bit damaged but still in 1 piece). Since i started flying turbine jets i have always dreamed of having a big projeti with a turbine engine. A few years back i found the gonzales project and found what i was looking for.... almost. I would really love a gfk fuselage and a jet for larger engines. Last year in Model city (http://www.modelcity.info/) i met a member of the gonzales team and i was hooked. When i got home i started my project the next day (June 2015) and now it looks like a plane  Still needs a lot of work....

Still needs a lot of work....I started with DevFuse to draw the fuselage. I used side and top views from the original projeti.

After cutting the foam layers of the fuselage and wing cores it looked like this:

The gonzales team had issues with the CG because of the short fuselage and the swept-back wings. I am creating a longer fuselage by moving the wings back. The first position was a bit weird end i ended up with a position that looked nice.

The fuselage looks nice and slim but is a lot wider then the projeti. It needs to be 170mm wide to accommodate a large engine. I want a simple P80 to fit but also a larger engine up to 18kg

First gfk part was also created

First gfk part was also created

Wings are made from a styrofoam core with 110g glass fiber cloth and 1.5mm balsa. This makes a very strong wing. A bit heavy but remember the 18kg turbine? It needs to be strong

It is only a 2m wingspan.... I had a alu tube lying around from a acrobatic plane and used that with newly created gfk tubes. I used the tube as a drill also.

It is only a 2m wingspan.... I had a alu tube lying around from a acrobatic plane and used that with newly created gfk tubes. I used the tube as a drill also.

The fuselage is about 120cm long and weights 950g from the mold. A bit heavy but also very strong.

All put together it looks awesome

I hope it can land very slowly with an high angle of attack.

I hope it can land very slowly with an high angle of attack.

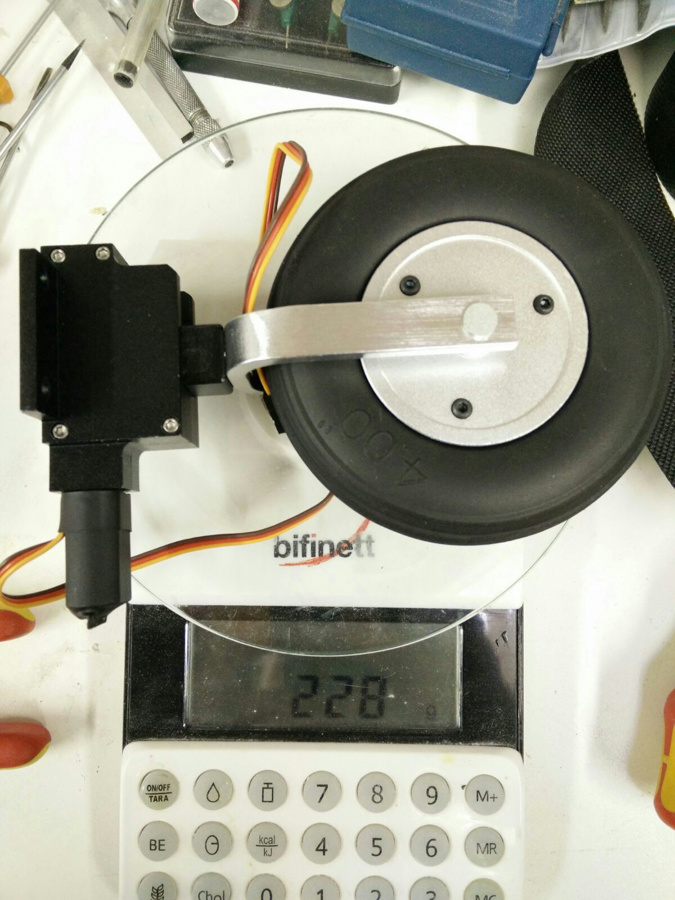

All parts are used or cheap. Engine has been modified and has a damaged turbine wheel, tanks are reused from a crashed plane, servos are used to (except the rudder servos). Receiver is worth the most to me

All parts are used or cheap. Engine has been modified and has a damaged turbine wheel, tanks are reused from a crashed plane, servos are used to (except the rudder servos). Receiver is worth the most to me