Cohesive

User gesperrt

Hi,

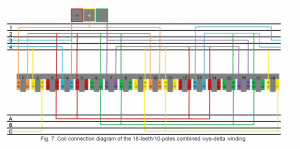

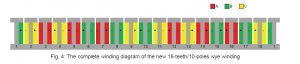

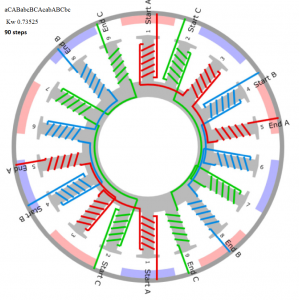

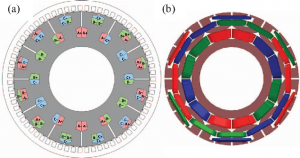

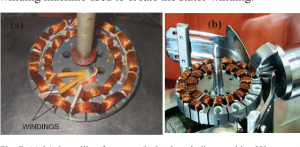

Most motor guys know the value of concentrated coils in motor construction. Most also know the downsides. There is relief that Dr. Dieter Gerling has created a semi distributed coil system for FSCW inductions machines and increase the performance dramatically. We have choices here. Do we leave it an induction machine or should we make it a large BLDC machine? I have one here out of the trash that was burned so I figured this might be a good time to experience experiment on this topic. I cleaned the rotor and body and decided why not try. Ill have to re-find the paper on this and post it but I was wondering are there any other cool ideas I overlooked?

Thanks

Hubert.

Most motor guys know the value of concentrated coils in motor construction. Most also know the downsides. There is relief that Dr. Dieter Gerling has created a semi distributed coil system for FSCW inductions machines and increase the performance dramatically. We have choices here. Do we leave it an induction machine or should we make it a large BLDC machine? I have one here out of the trash that was burned so I figured this might be a good time to experience experiment on this topic. I cleaned the rotor and body and decided why not try. Ill have to re-find the paper on this and post it but I was wondering are there any other cool ideas I overlooked?

Thanks

Hubert.