Hi to all fans of F3X models, hope you weren´t be annoyed due to my english, sorry for that.

But I believe that for most of pilots will be this buildlog useful.

After long thinking about right plane for new category F3G,

I made decision for FS6, due to lots of experinces from well known team www.tud-modelltechnik.de.

They confirm their quality by numerous winnig in close category F3B and F3F for long time.

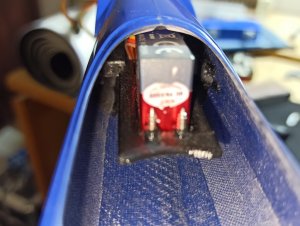

At the beginnig some photos,.

Build log will be follow, stay tunned

Milan

But I believe that for most of pilots will be this buildlog useful.

After long thinking about right plane for new category F3G,

I made decision for FS6, due to lots of experinces from well known team www.tud-modelltechnik.de.

They confirm their quality by numerous winnig in close category F3B and F3F for long time.

At the beginnig some photos,.

Build log will be follow, stay tunned

Milan