Lew Zee

User

In January of this year (2022) I was given a Krick Dusseldorf 2 fireboat. It was about 85% built and partially running. The previous owner bought it as a project to work on during the Covid epidemic. However, I don't think he was experienced enough to build a working model of this level of complication. One of the big problems was that he had an eight channel Spektrum RC system and he was trying to get some channels to operate more of the functions. (He had extra servos and switches he was trying to use.)

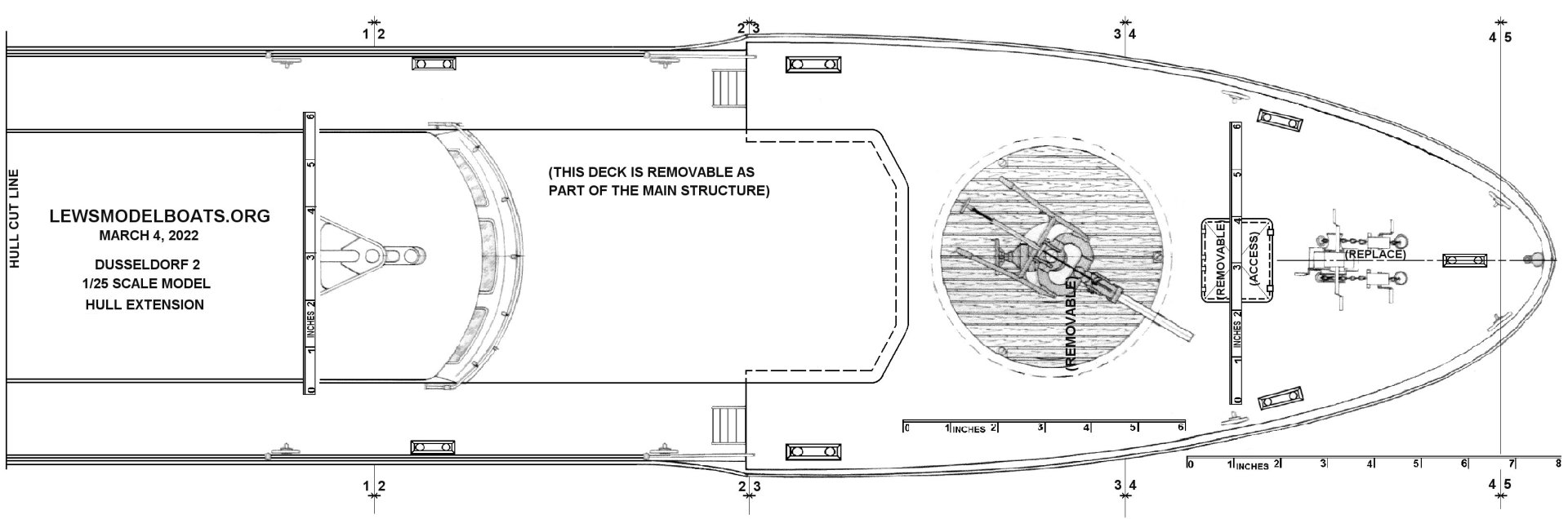

I decided to do some historical research on the real fireboat (like I do for most of my models). At first I thought that Robbe did not make the boat to be a model of the real Dusseldorf. Then I found out that in 1979 the real fireboat was lengthened. That I what I decided to do with this model.

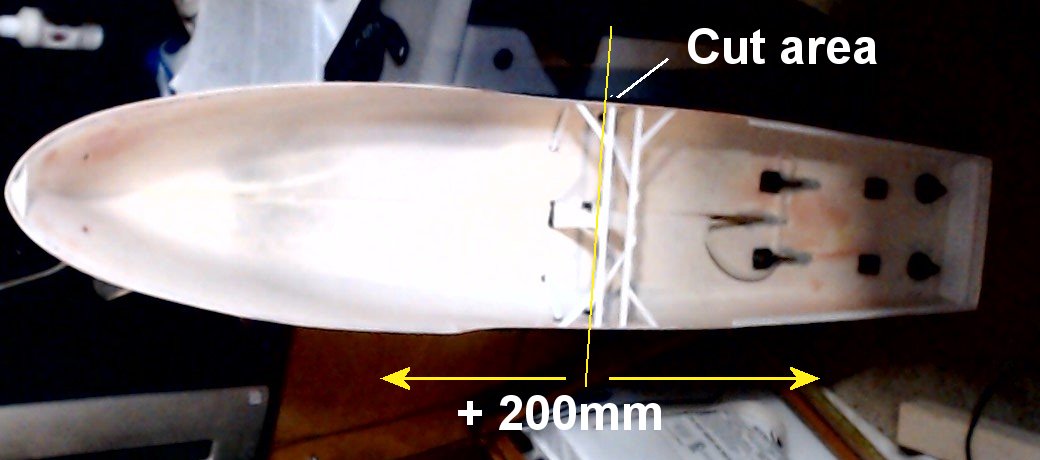

So I just about completely disassembled the model, removed the decks and all of the wiring and am preparing the hull to be cut and rejoined with a 200mm new center section. I see that at least two other model builders (both in Germany) have done this but for their own reason the stopped many years ago.

If you or anyone you know has done this can you/them post on this forum topic. I would like to hear/see what others have done. This should make a very interesting model when completed.

I plan on posting updates here now and then, but for more details and photos I have created some pages for the Dusseldorf 2 fireboat on my web site at: (I also have a highly detailed Graupner Wiesel, with a lot of info on that is on my site as well.)

Lew

Clearwater, FL, USA

I decided to do some historical research on the real fireboat (like I do for most of my models). At first I thought that Robbe did not make the boat to be a model of the real Dusseldorf. Then I found out that in 1979 the real fireboat was lengthened. That I what I decided to do with this model.

So I just about completely disassembled the model, removed the decks and all of the wiring and am preparing the hull to be cut and rejoined with a 200mm new center section. I see that at least two other model builders (both in Germany) have done this but for their own reason the stopped many years ago.

If you or anyone you know has done this can you/them post on this forum topic. I would like to hear/see what others have done. This should make a very interesting model when completed.

I plan on posting updates here now and then, but for more details and photos I have created some pages for the Dusseldorf 2 fireboat on my web site at: (I also have a highly detailed Graupner Wiesel, with a lot of info on that is on my site as well.)

Lew

Clearwater, FL, USA

Zuletzt bearbeitet: