O.K., um das hier am Laufen zu halten. Der erste imrprovisierte Bausatz ging an einen Freund in den USA, der mir bei der eralisierung der Nautilus sehr geholfen hat. Ohne Ihn wäre das Boot nicht so schön geworden. Er schreibt einen Work In Progress Report und ich werde den hier nach und nach auch posten. Leider nur in Englisch. Ach ja, Ladies und Gentlement.....die Arbeit von David Merriman:

I first became aware of the model work of Andreas Schmehl a few years back while

checking out the articles at one of the few forums dedicated to r/c submarine model

building. His work-in-progress (WIP) -- a format of article writing that is heavy on inprogress

photos with supporting text -- dealt with the construction of a 1/23 scale, U-1.

Germany's first combat submarine. It was the most comprehensive and well laid out

WIP I had ever read.

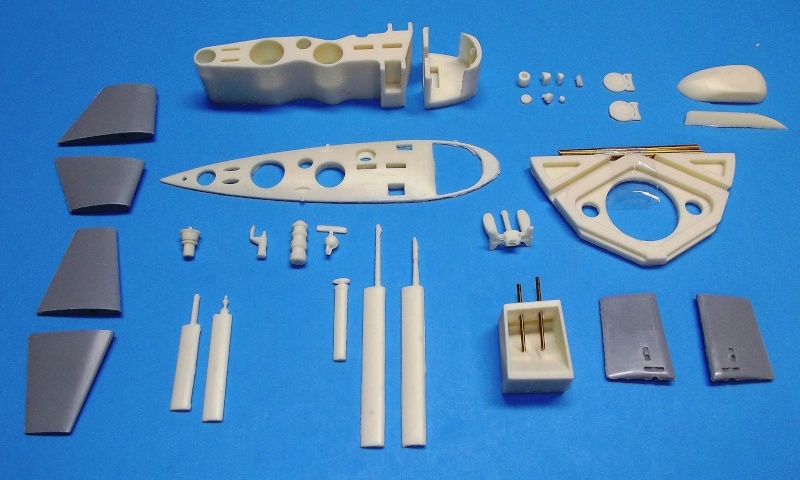

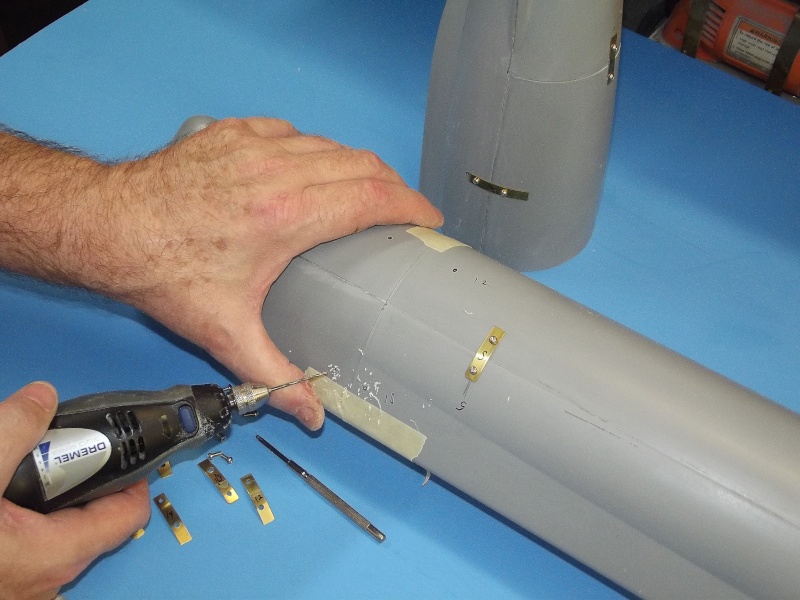

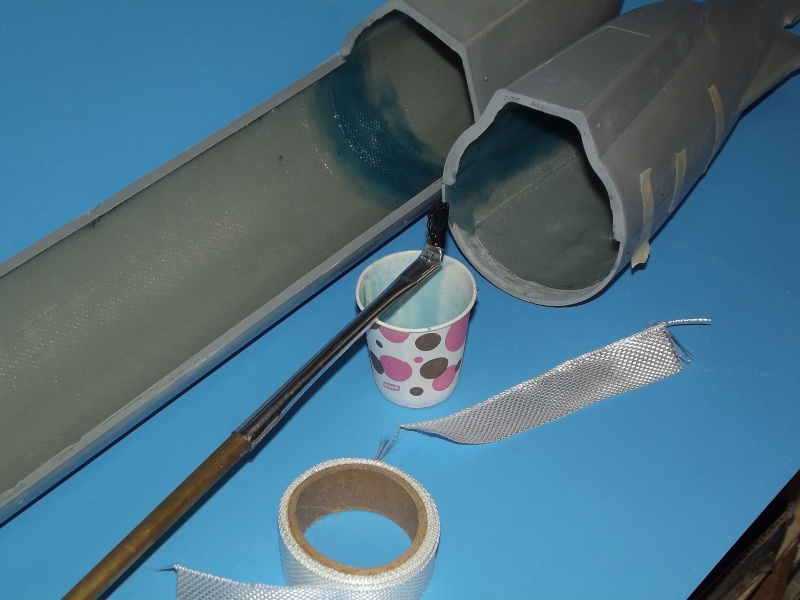

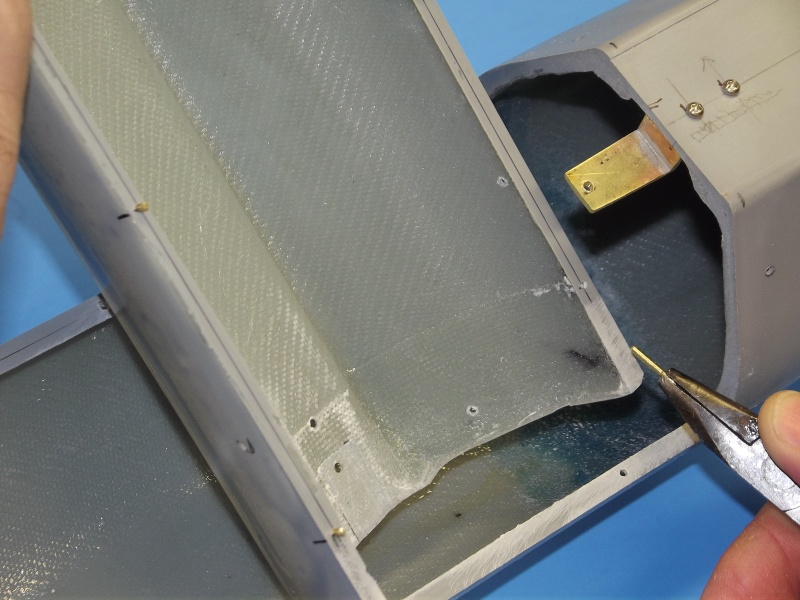

That multi-part article had everything: CAD design, CNC'd hull masters; 3D printed

detail parts; hard-shell, GRP hull tools; RTV rubber tools for the small stuff; GRP lay-up;

resin casting; WTC design and manufacture; trimming; detailing; and painting.

As Andreas put it: "I mainly use CAD to create a virtual model of the hull and the interior

technical structure. From that I produce the 3D files for manufacturing 3D-printed parts

and for milling preforms for the GRP tooling". What Andreas calls 'preforms' we

American's understand these as masters, or patterns.

Once Andreas had worked out the 'plans' in CAD, he sent the files to a second party

fabricator who used them to cut machinable plastic medium via CNC milling machine,

and to poop out plastic parts via 3D printer. Those parts, back in Andreas' hands,

becoming the masters of off which he would produce the actual model parts.

Masters by robot. Tooling and model parts by the good doctor.

SkyNet, call your office!

His U-1 article showed me, in a very well laid out article, the use of computers and

mechanized subtractive and additive item manufacture as part of the model building

process.

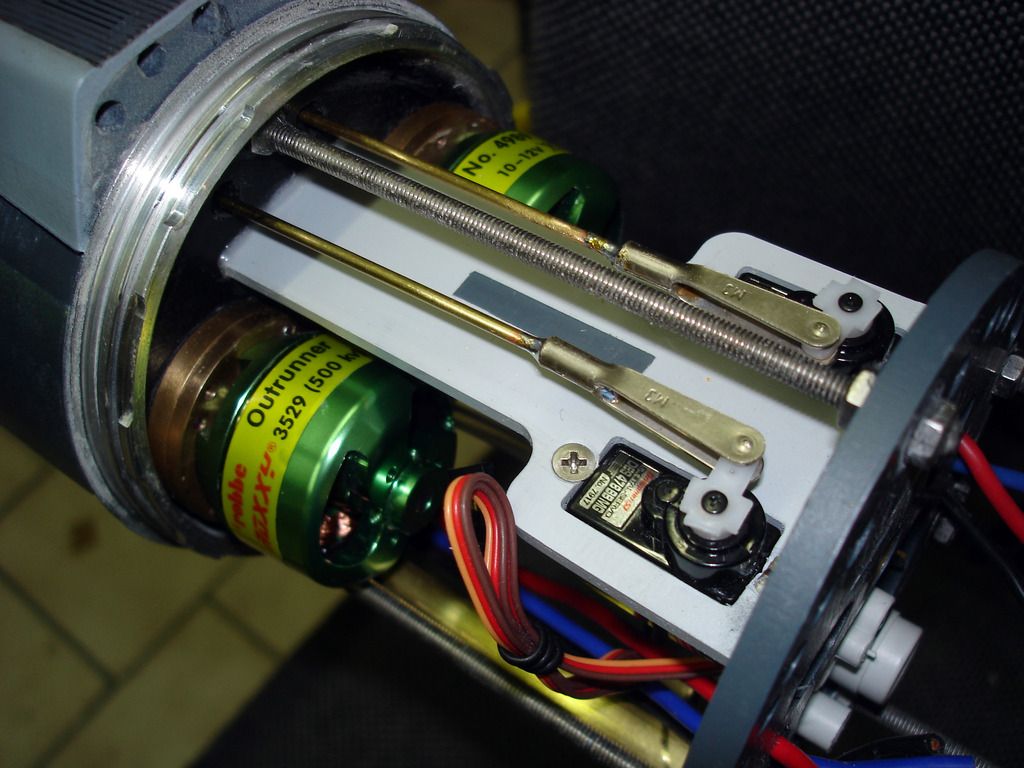

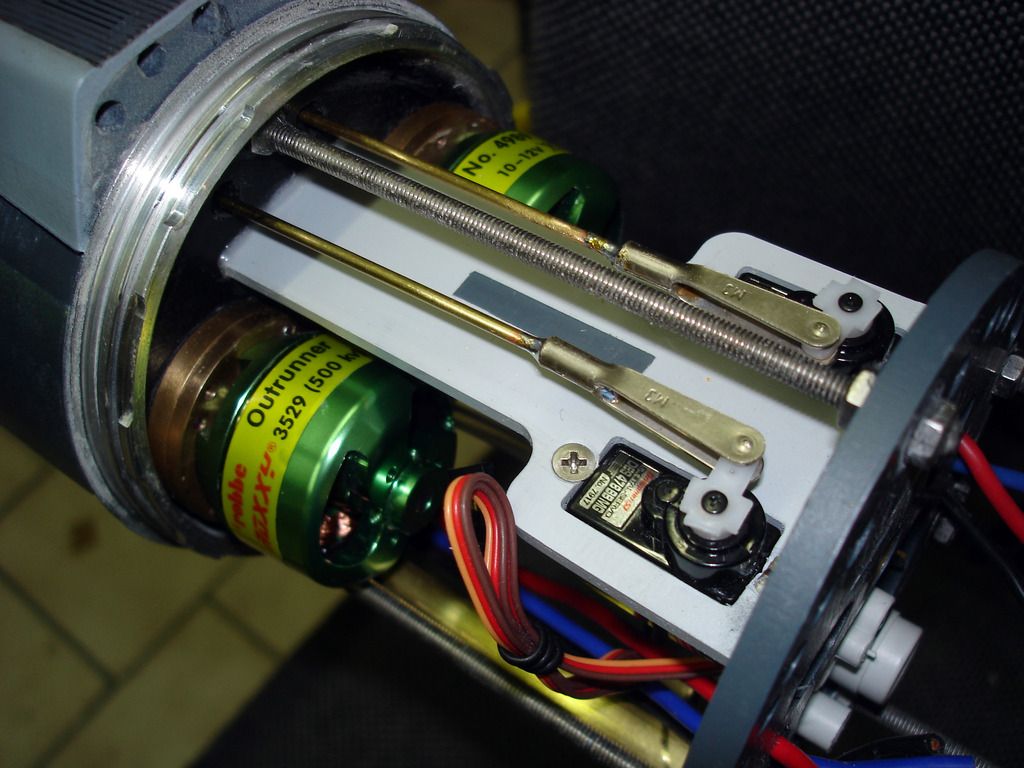

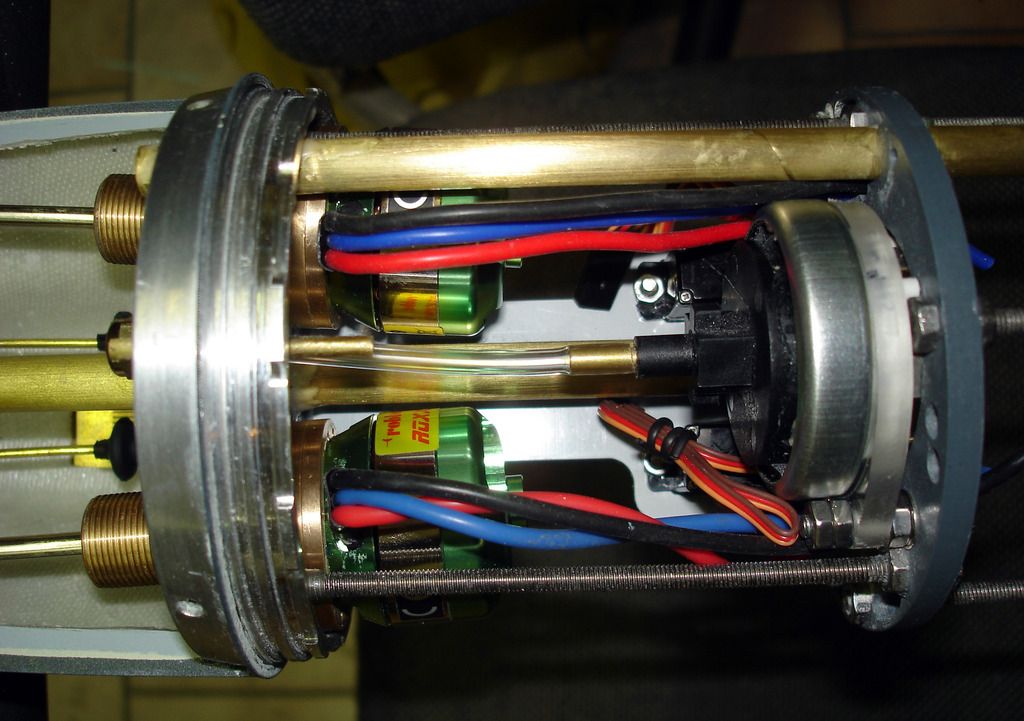

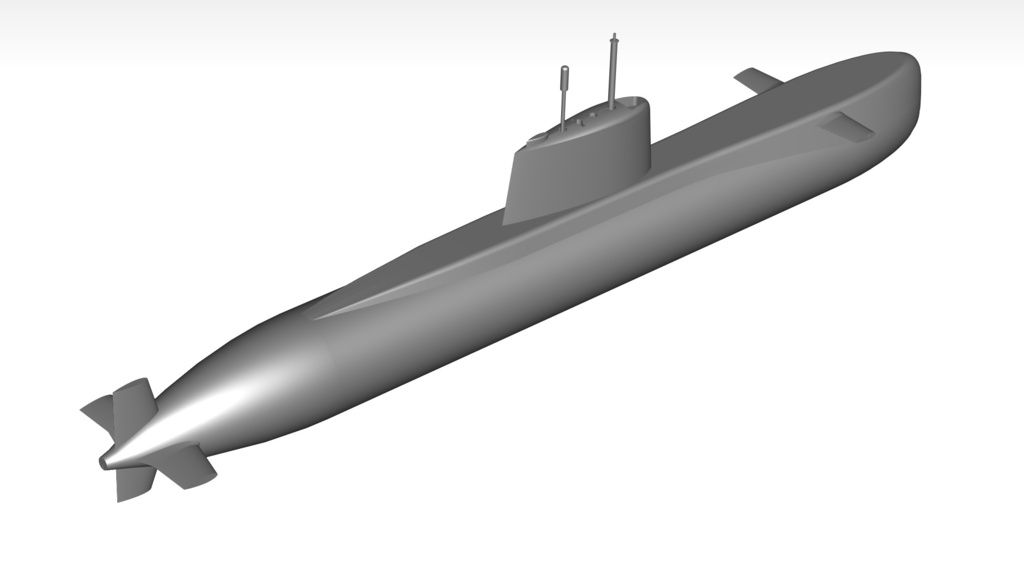

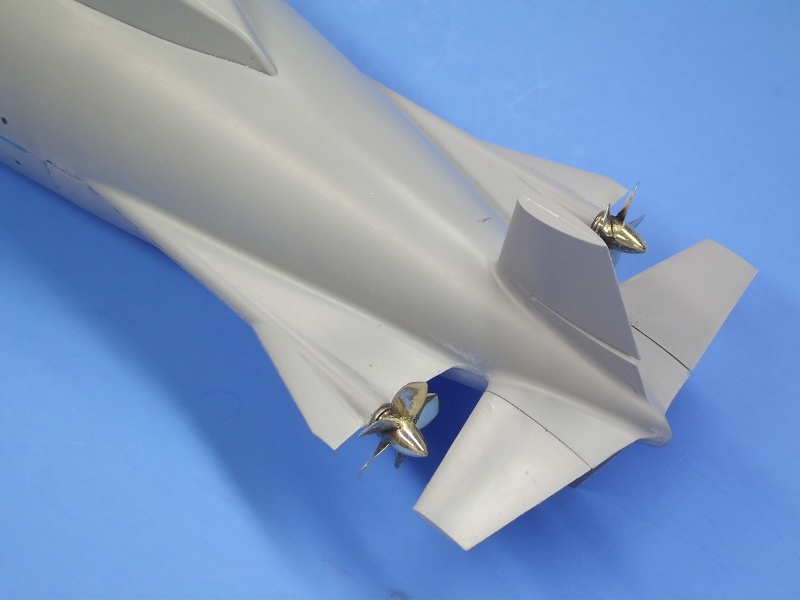

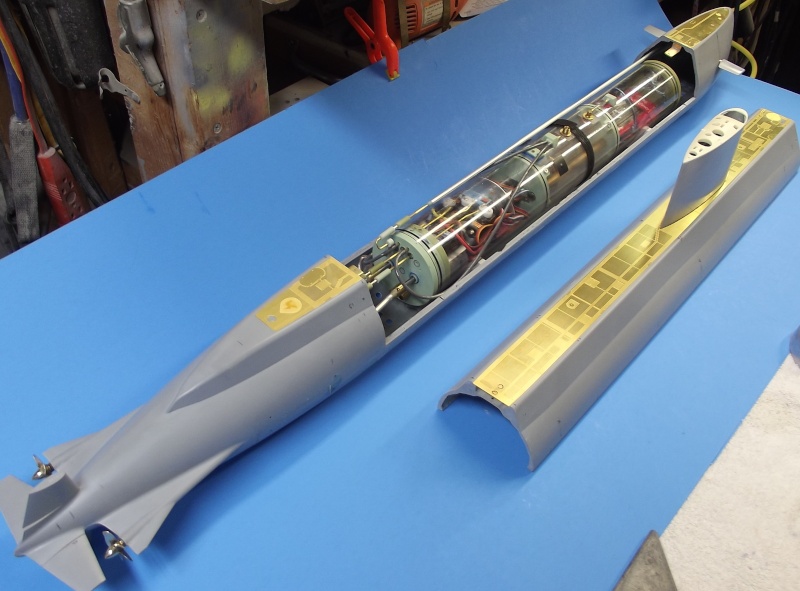

Andreas has done the same thing with his current r/c submarine project: a dry-hull 1/87

scale model kit of the famous, USS NAUTILUS.

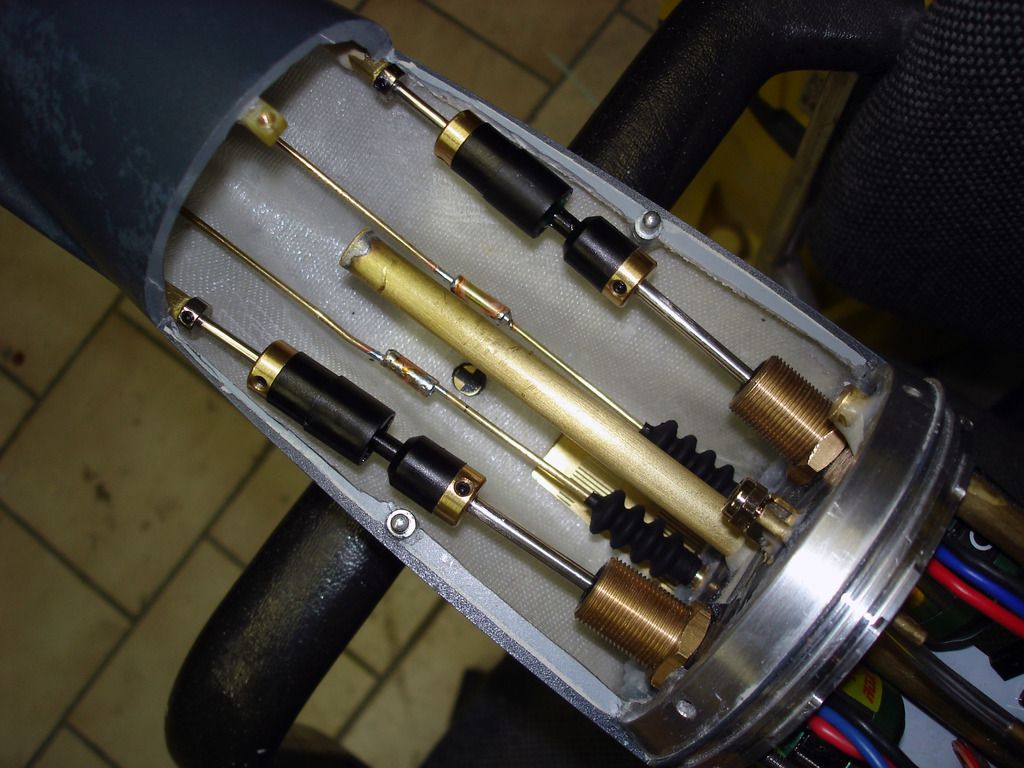

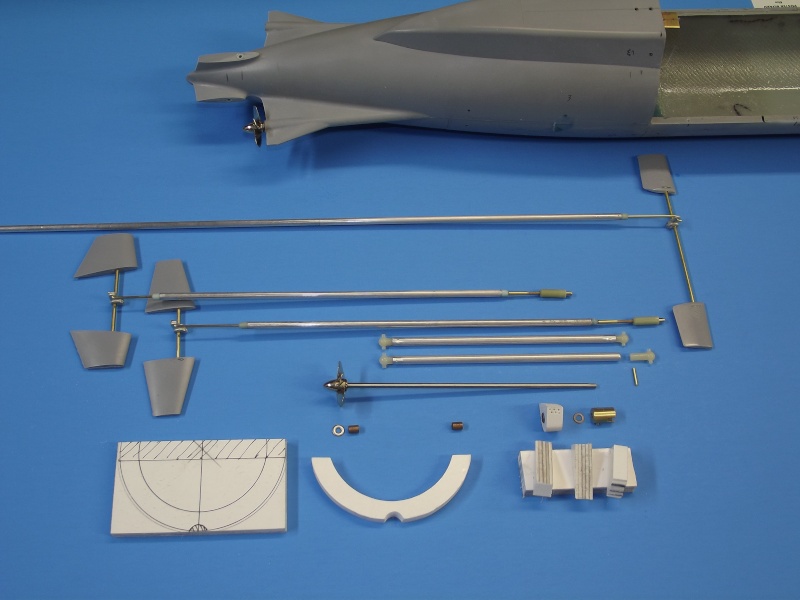

His first USS NAUTILUS, assembled from his kit -- as is the European practice -- was

configured as a dry-hull type r/c model submarine. With the exception of the sail and a

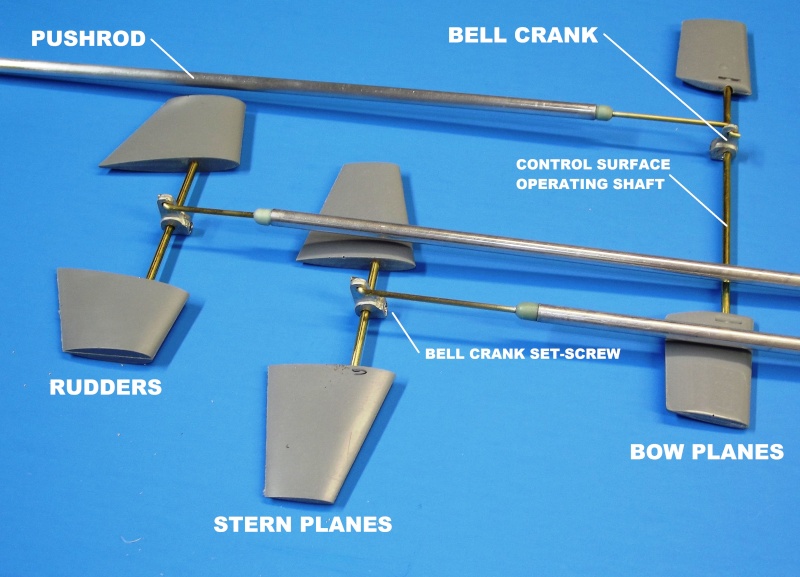

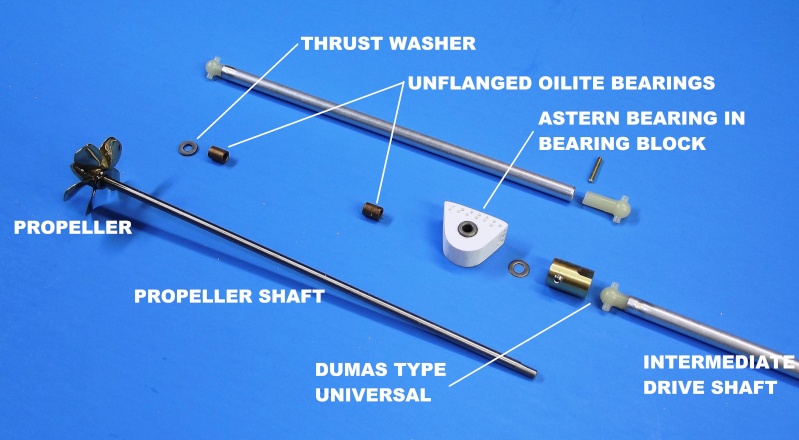

portion of the stern (where the stern plane, rudders and propeller shafts make up to

their respective running gear and linkages) the entire hull is dry.

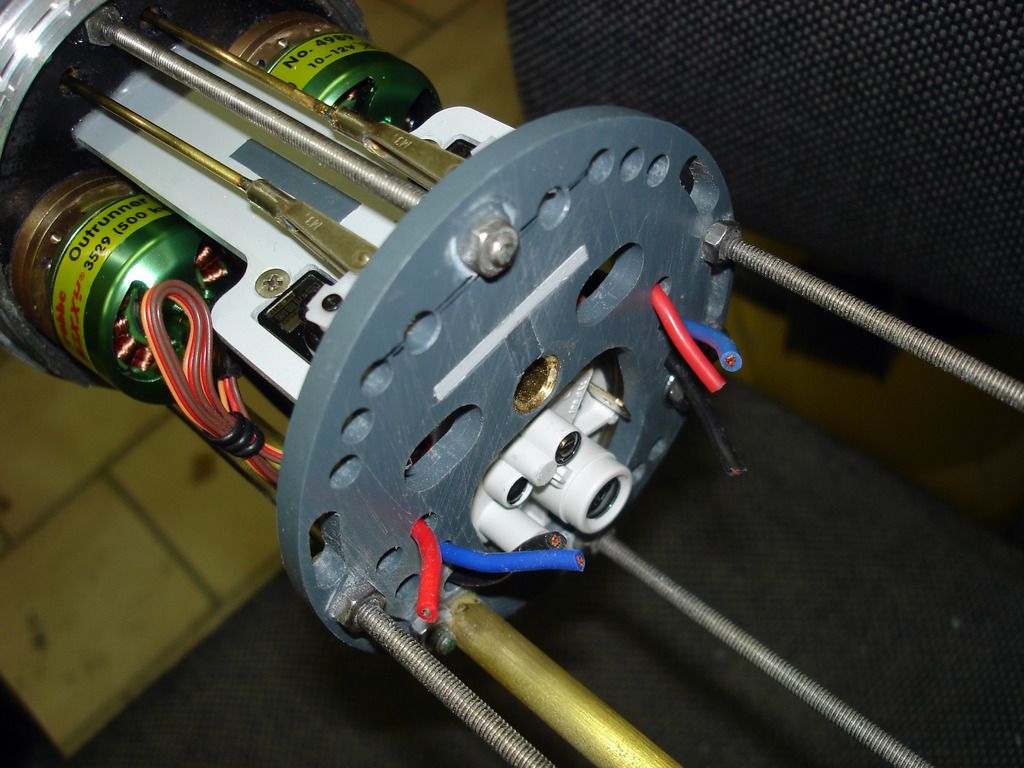

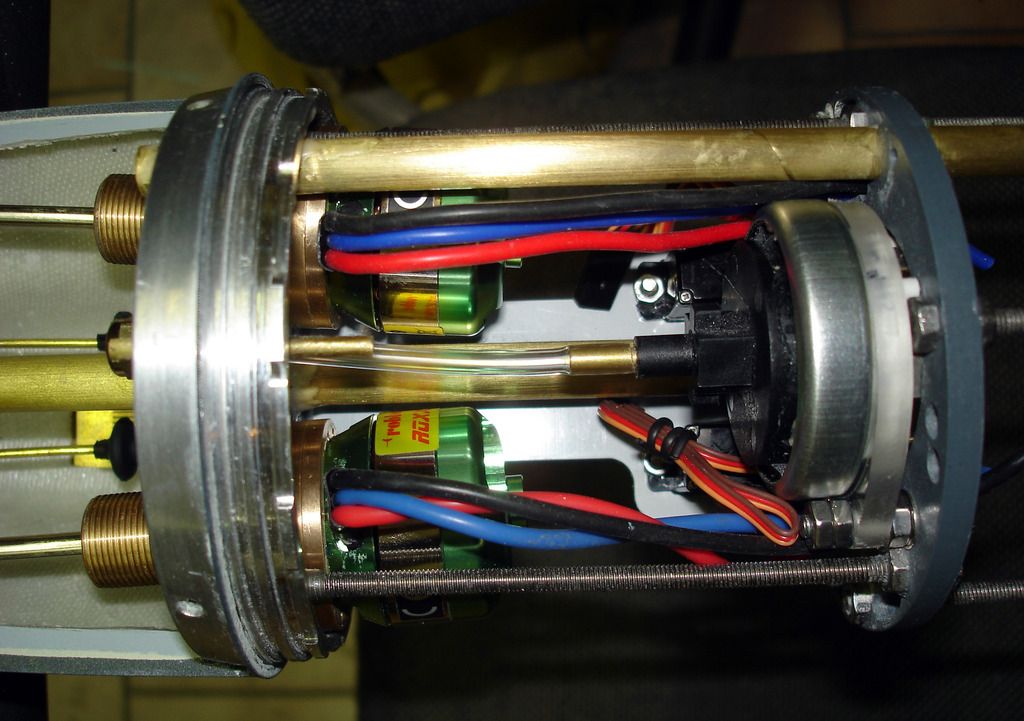

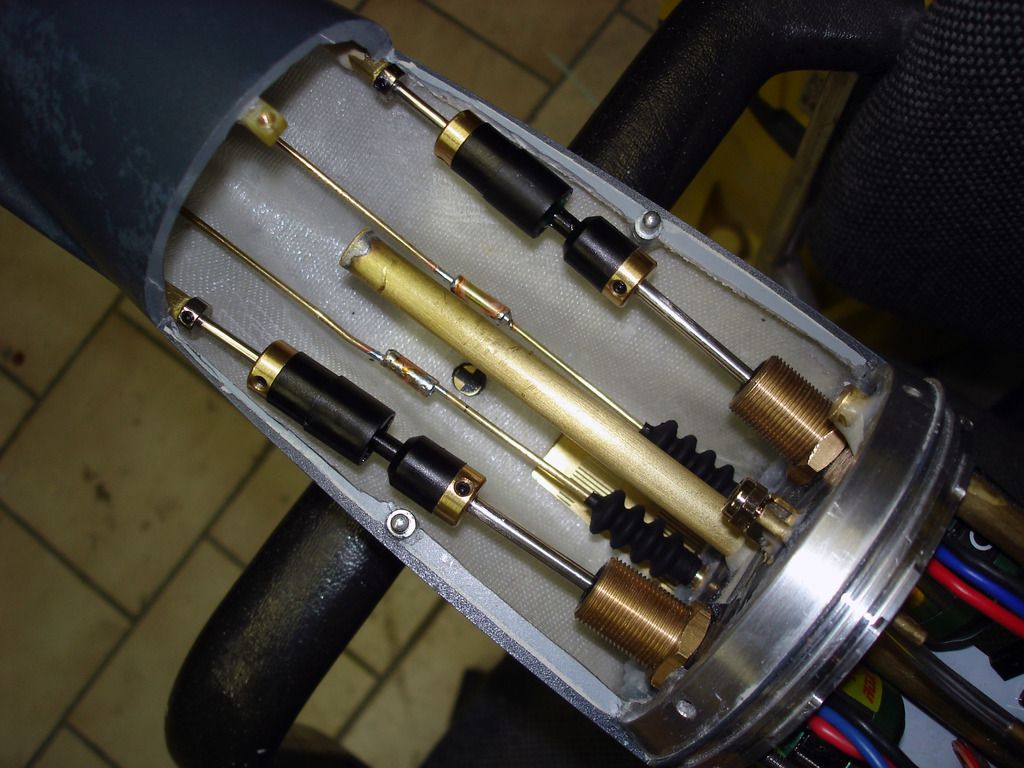

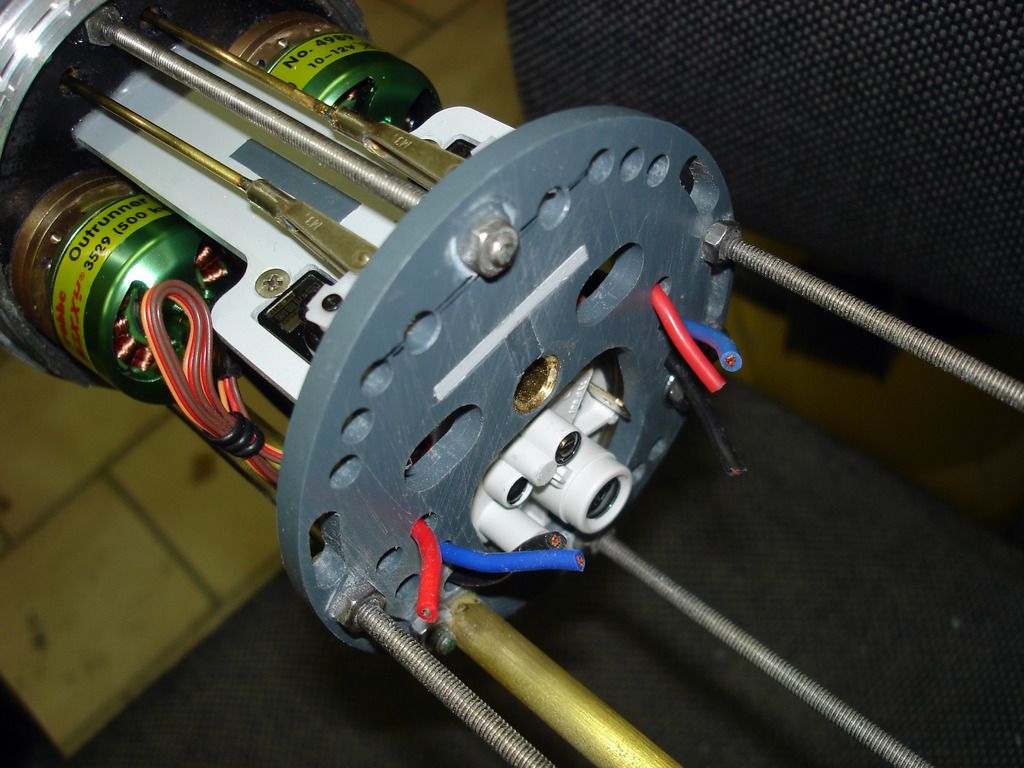

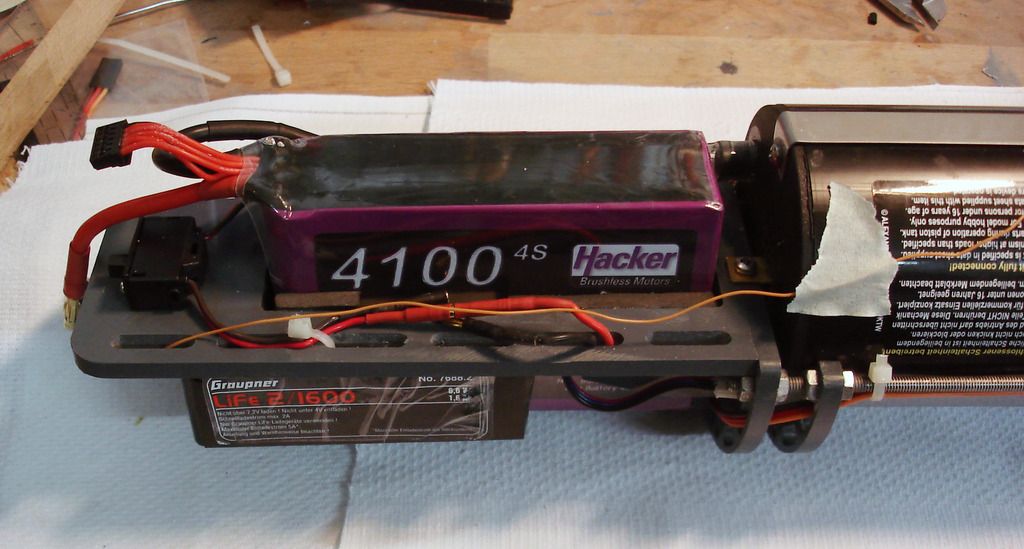

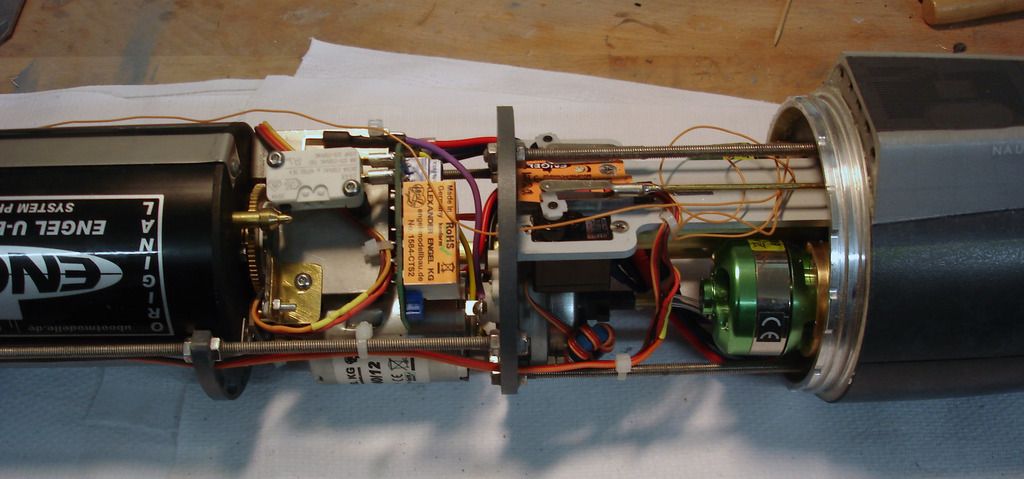

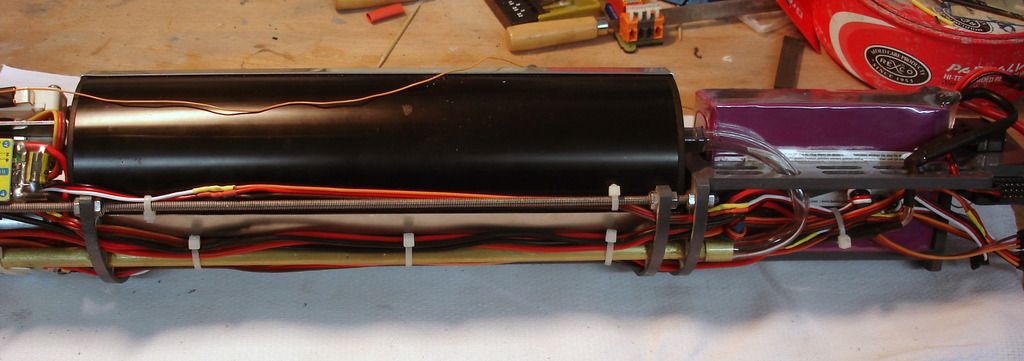

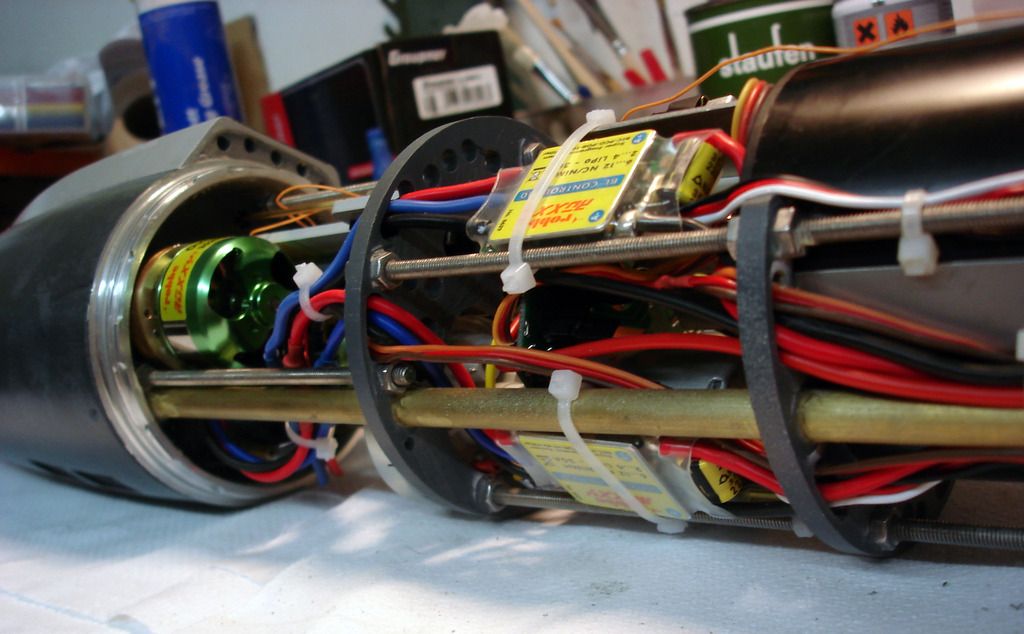

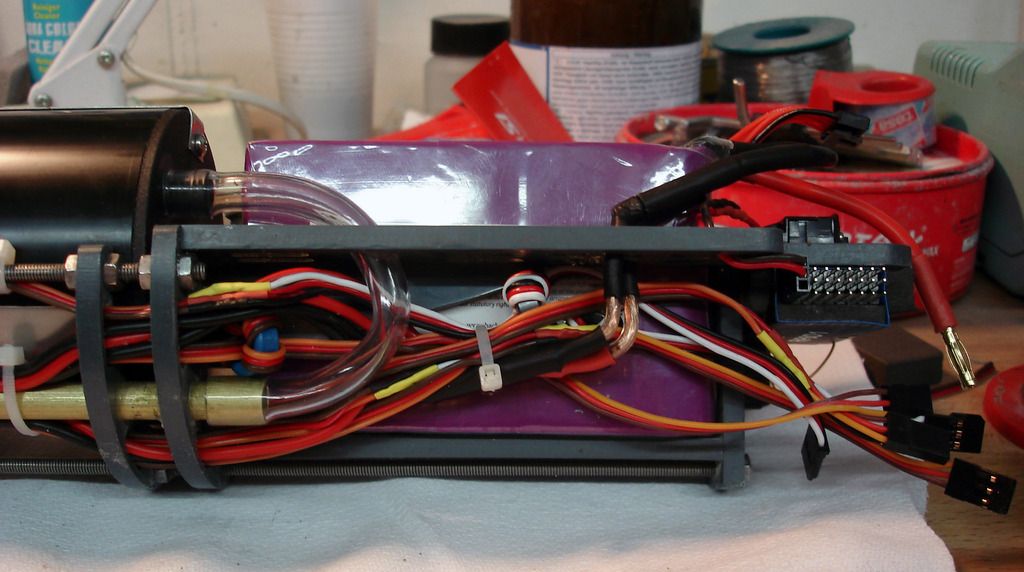

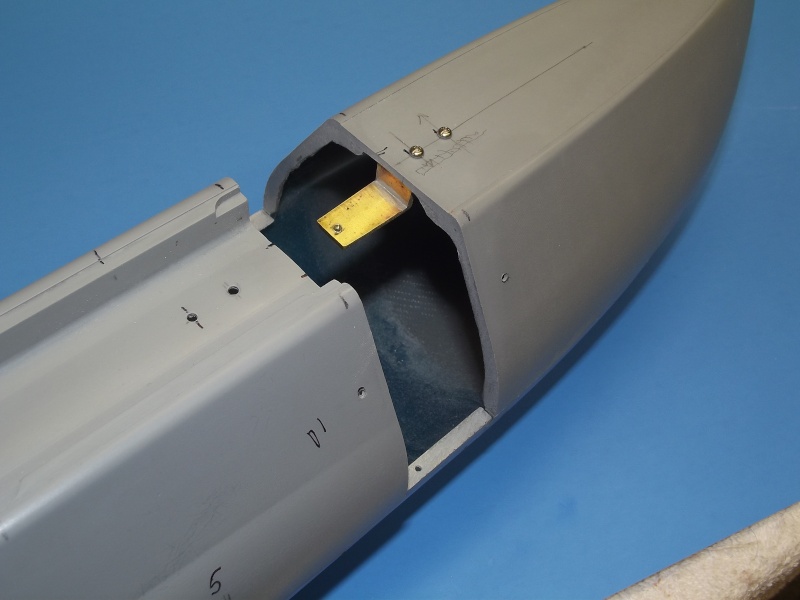

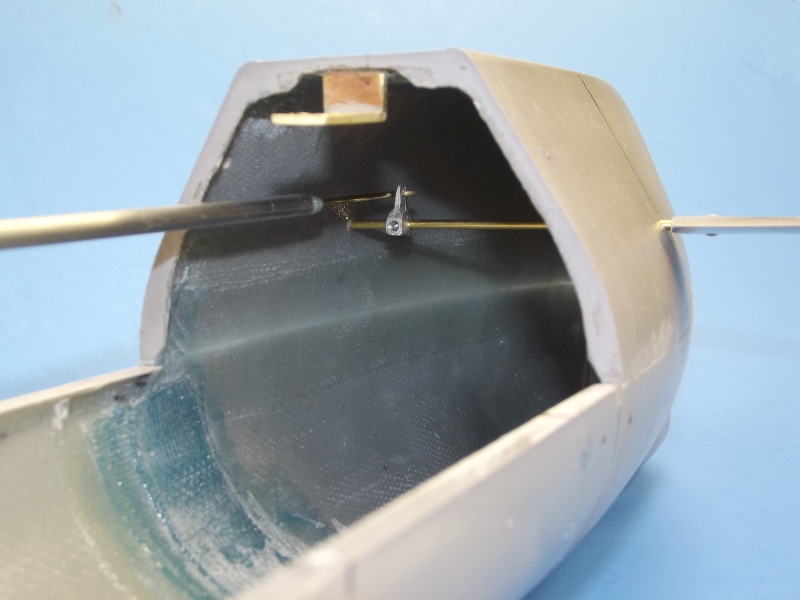

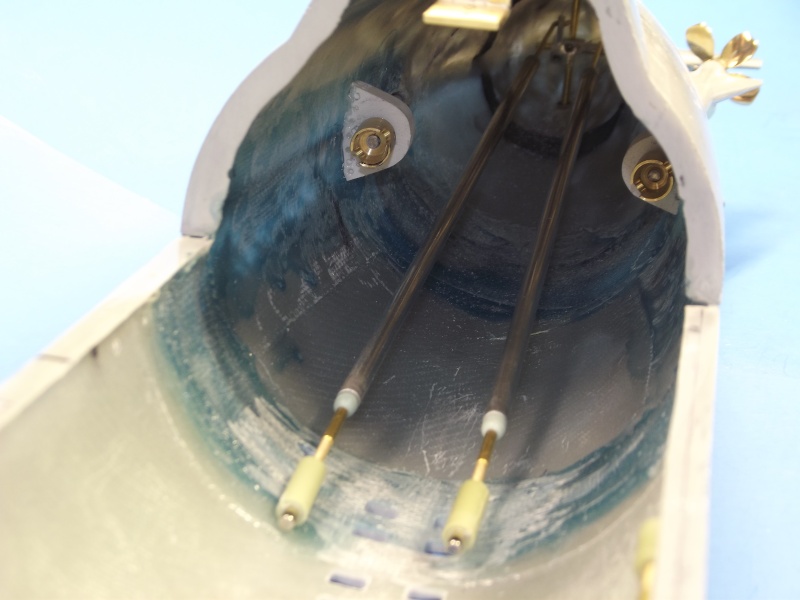

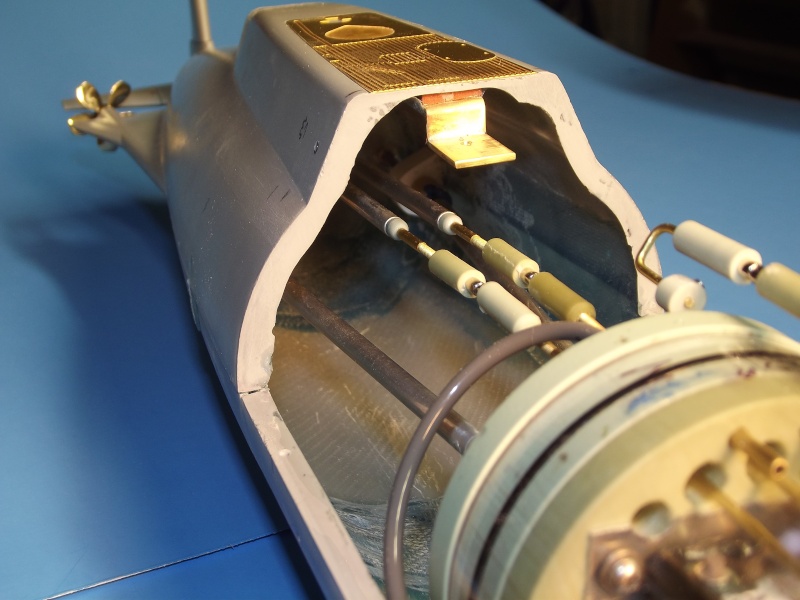

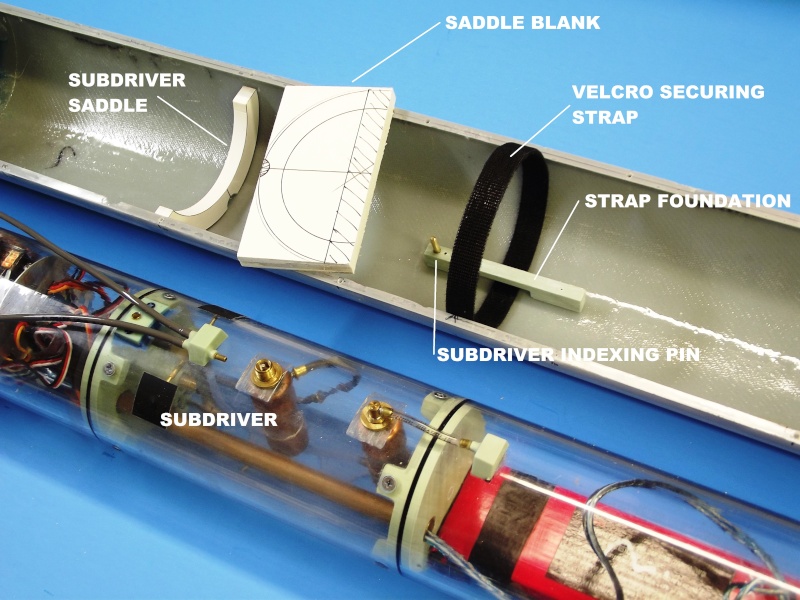

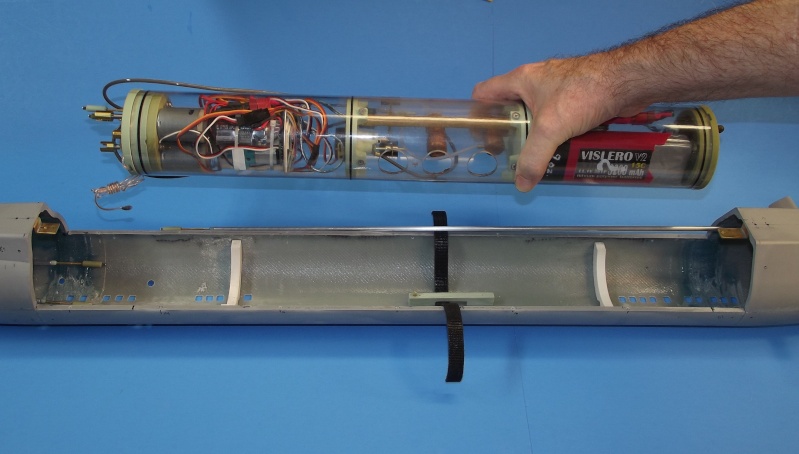

Another European practice -- most suitable for dry-hull types r/c submarines -- is to

access the interior through a set of bayonet rings that seal with an o-ring. Set into the

forward and after sections of the model, the bayonet rings produce a radial break

between the two. To access the interior all that is required is a slight rotation of the hull

halves to free the lugs of the bayonet rings and simply pull the two hull halves apart. A

positive, quick, easy and pressure-proof closure method. Attaching the equipmentdevice

mounting structure to the stern exposes everything when the forward section of

hull is removed.

Unlike wet-hull type models -- which require opening the hull through a horizontal

equatorial break, removing the WTC, and only then gaining access to the devices by

removing the end-caps of that WTC -- the dry-hull bayonet rings make for excellent

access to the internals for repair, de-watering, adjustment and maintenance tasks.

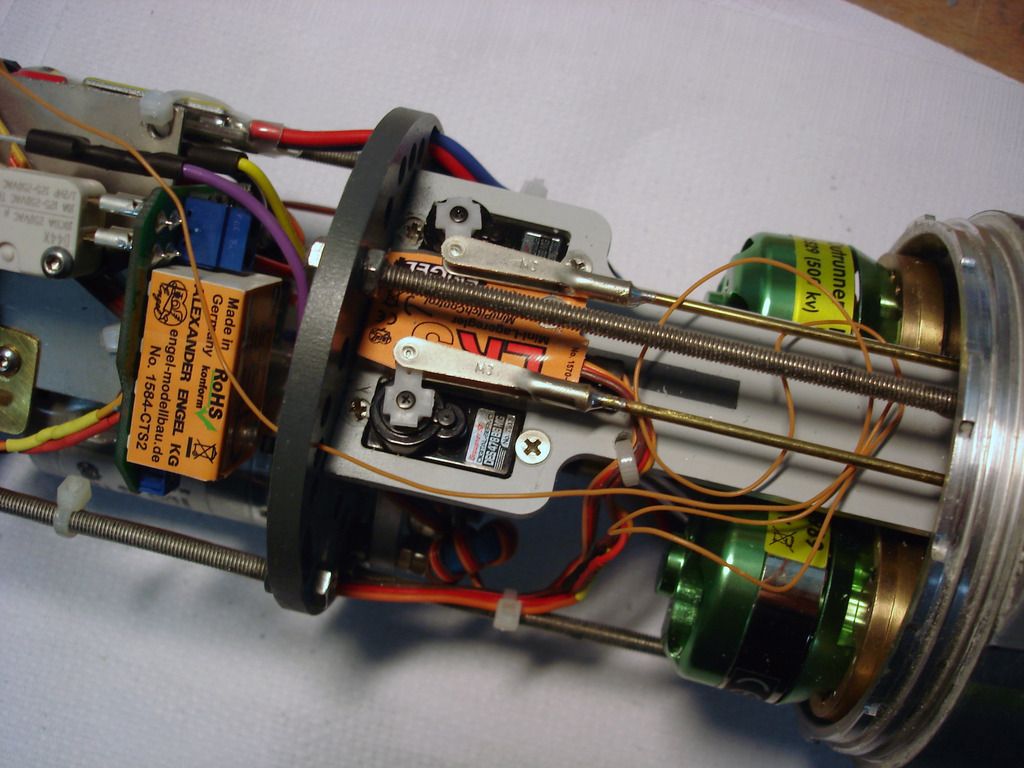

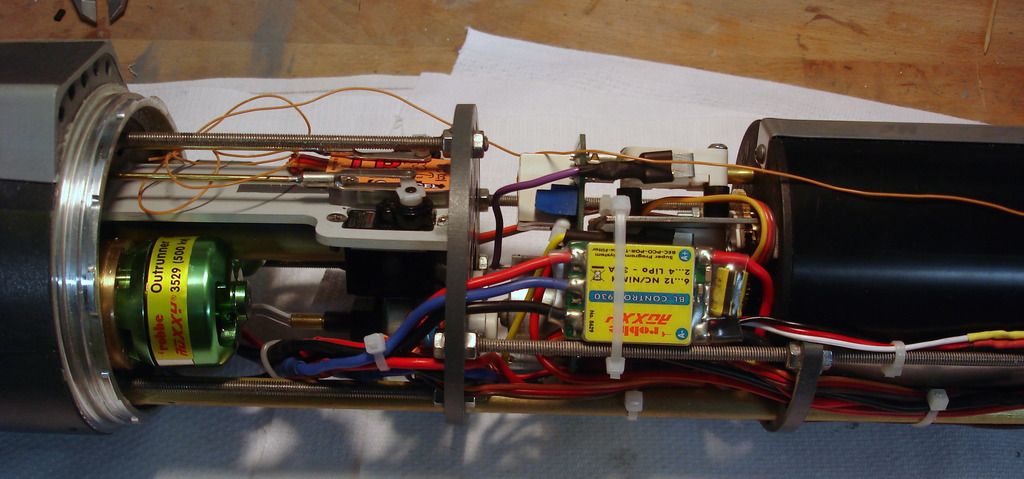

The advantage of the dry-hull is that there is plenty of available volume in which to stick

all the propulsion, control, and ballast sub-systems.

However, as the superstructure and portions of hull above the waterline will displace so

much water when they are immersed, it takes a great deal of water weight --- taken into

an internal ballast tank -- to create the force needed to counter the buoyant force

produced by all that displacing structure. A big ballast tank takes up valuable real-estate

within the tight confines of the hull.

The need for such a large internal ballast tank denotes the major disadvantage of the

dry-hull type submarine.

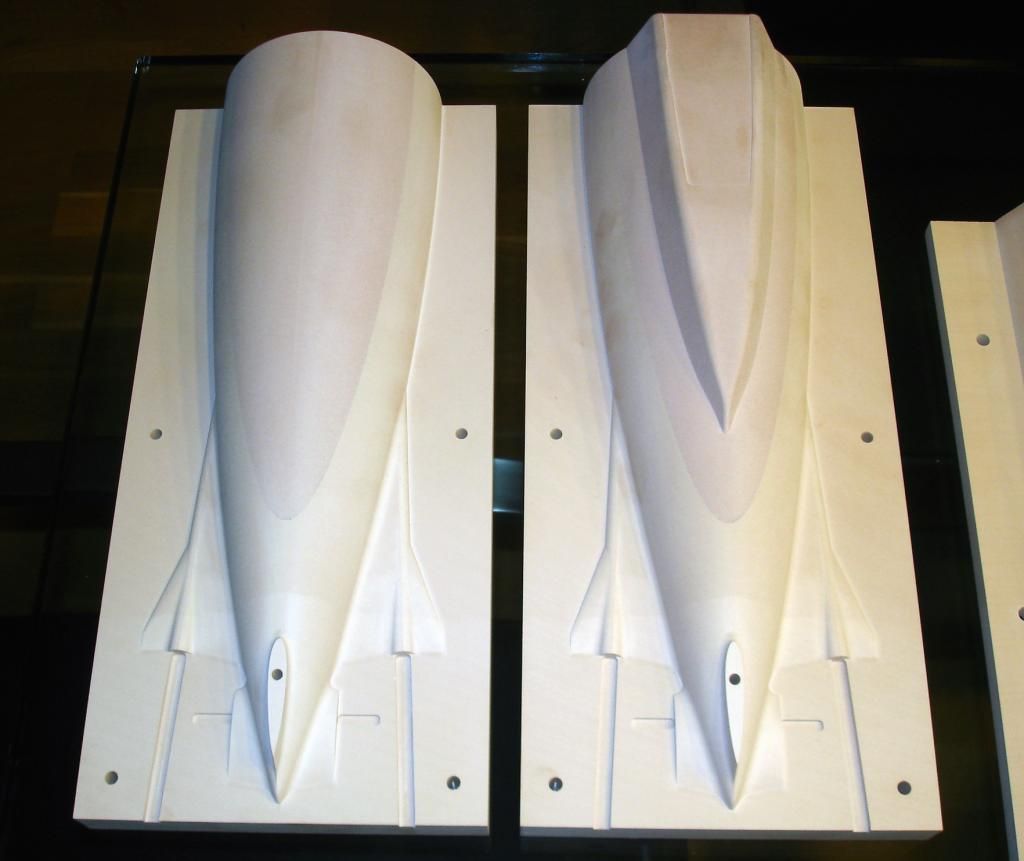

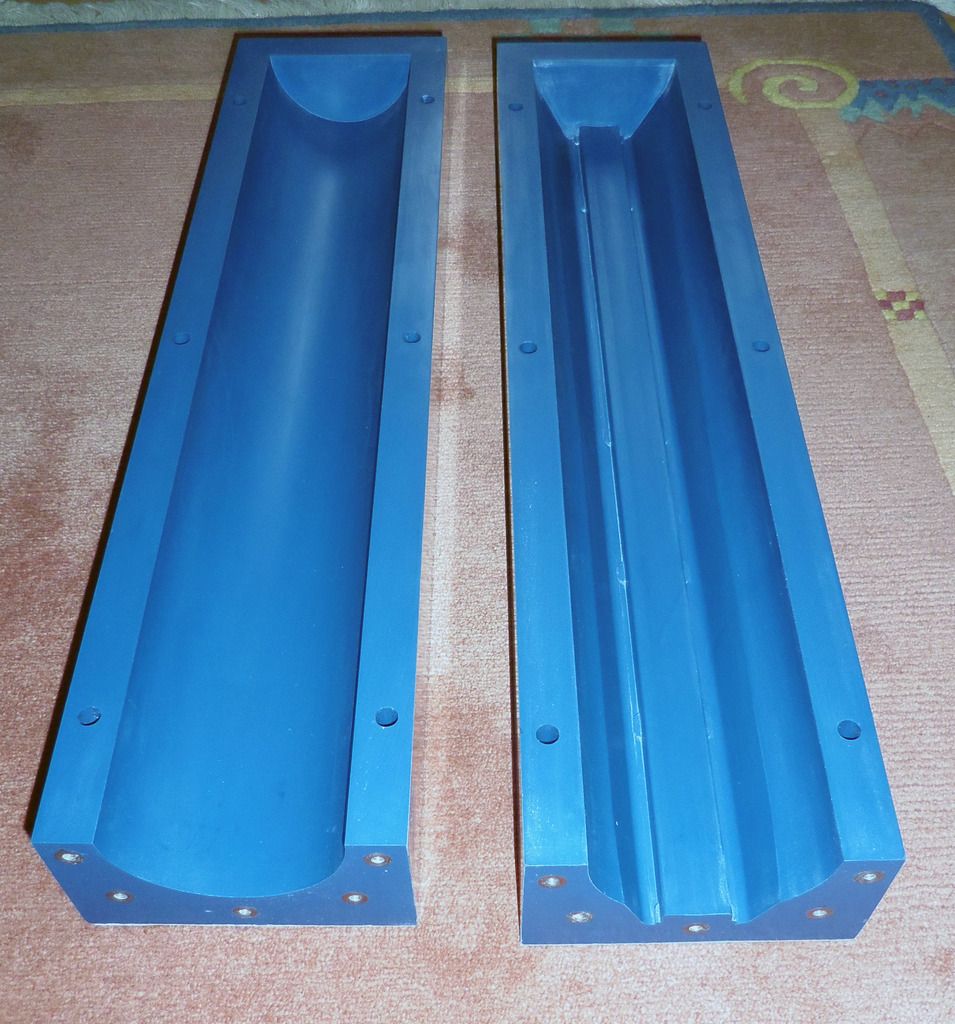

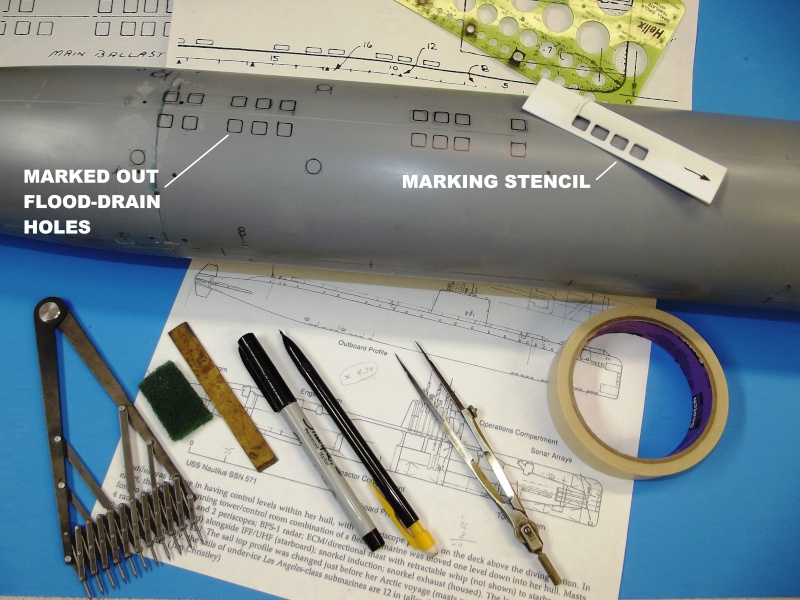

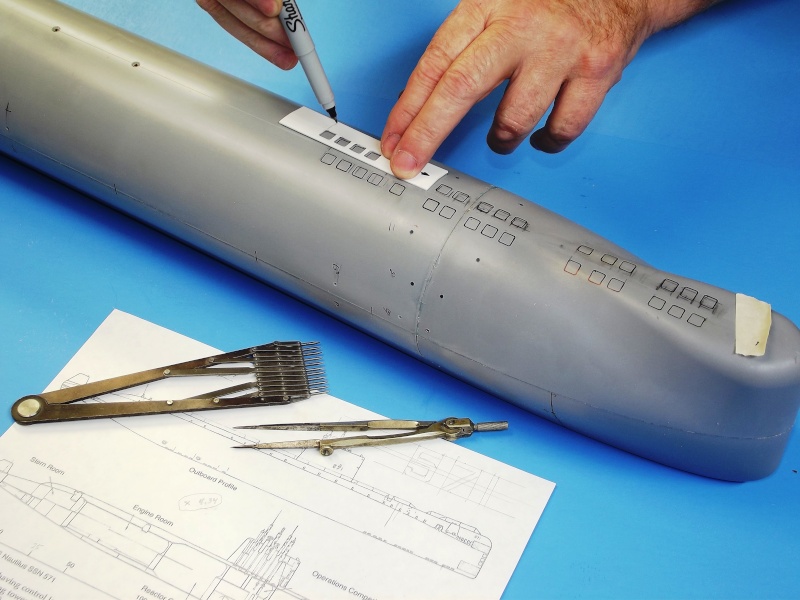

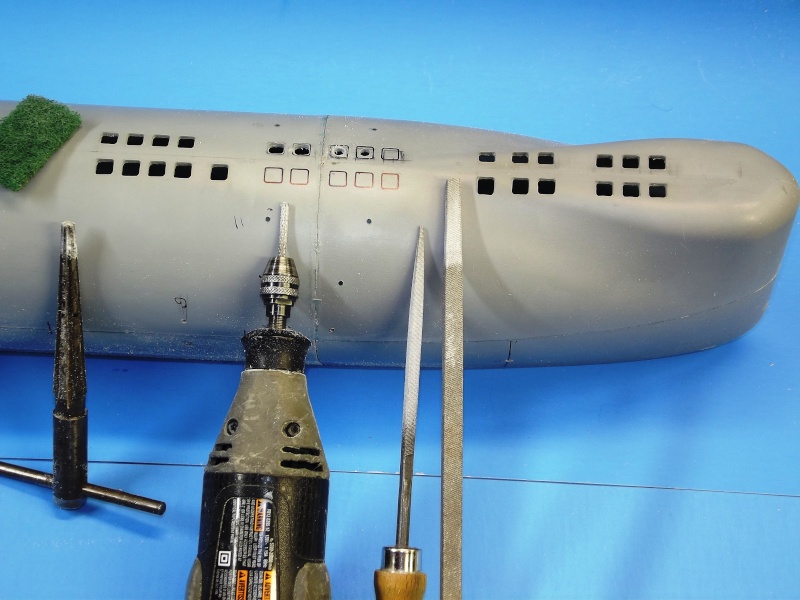

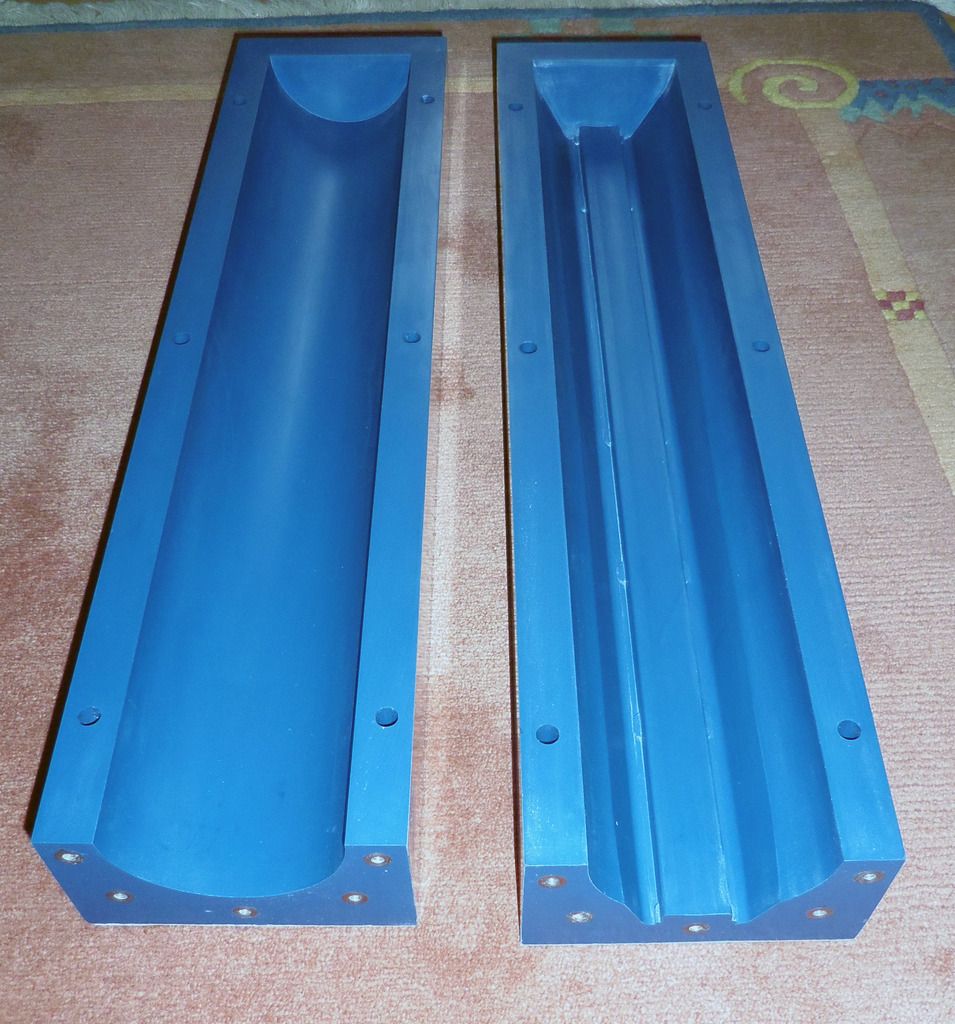

Andreas followed the same manufacturing methodology with his NAUTILUS kit. A

second-party produced the masters from which he would make to tooling needed to

create the model parts. Here we see some of the CNC milling-machine cut masters.

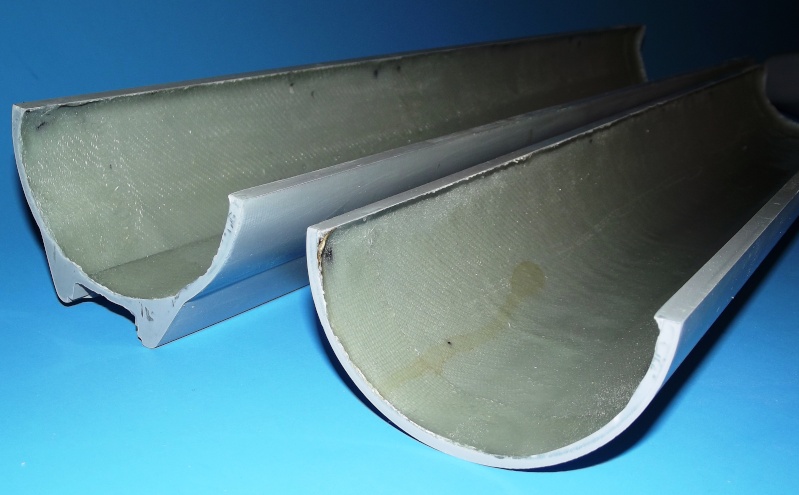

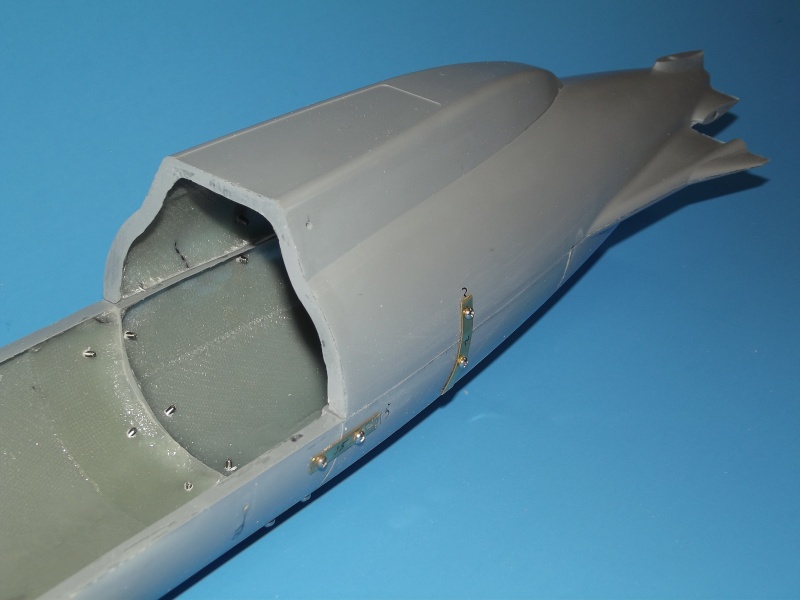

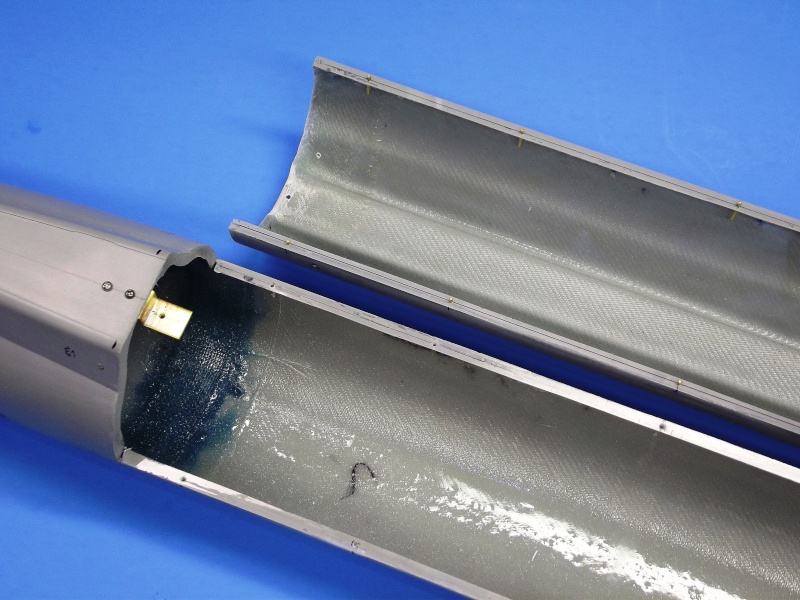

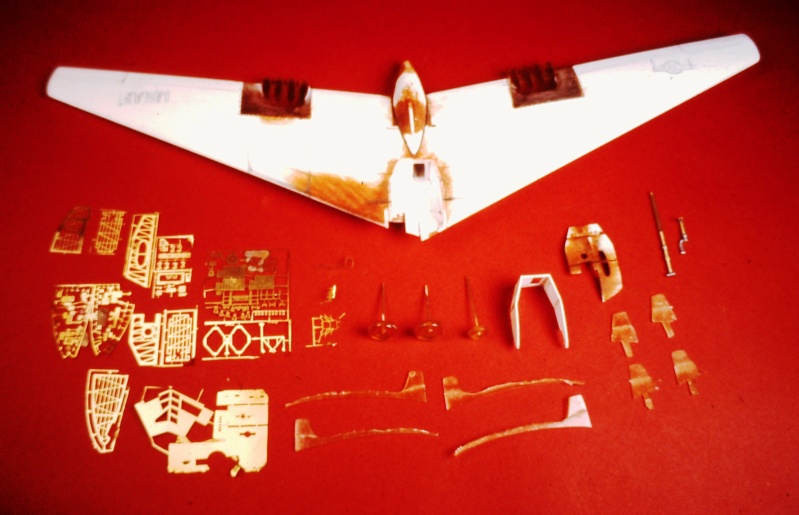

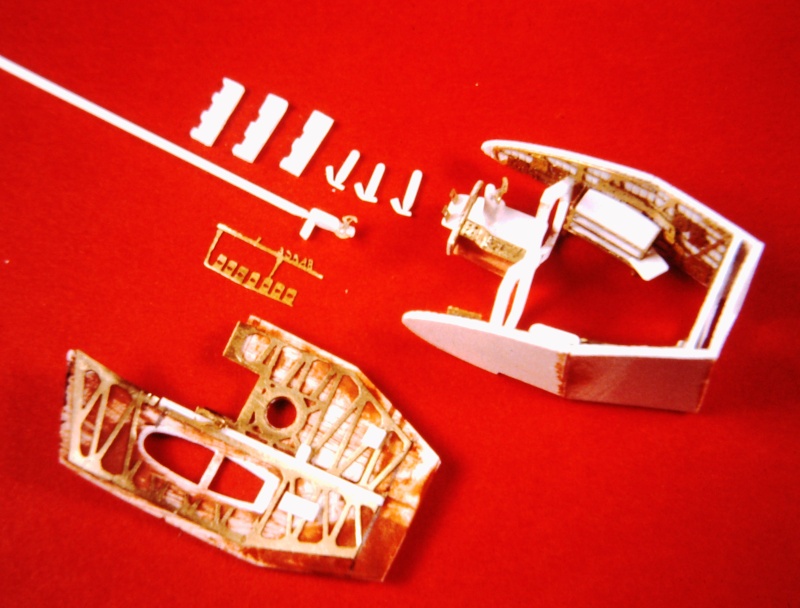

Off those CNC cut masters Andreas laid-up these GRP hard-shell tools. A total of eight

tools required to render all the hull and sail parts. Those GRP parts rendered as very

thin section structures.

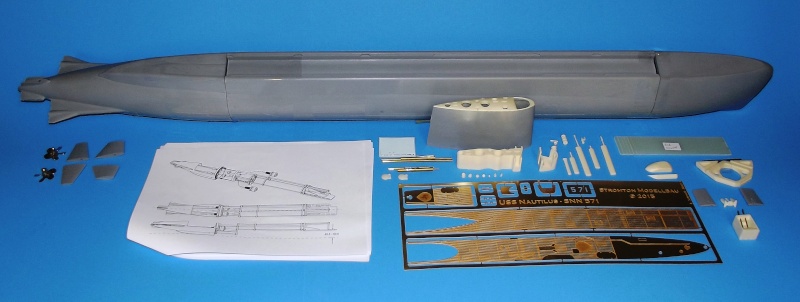

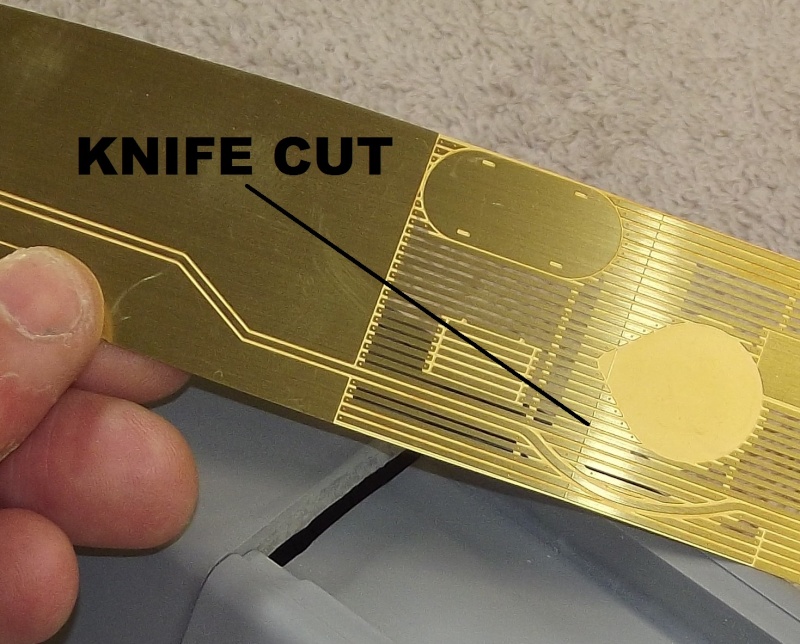

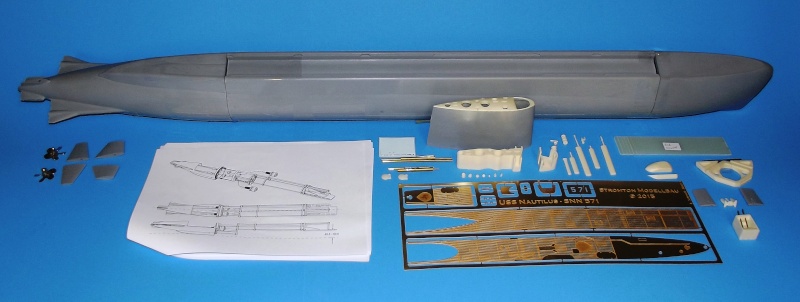

In addition to the resin and GRP parts he produced from this tooling, Andreas also

produced the art work from which he had acid-etched a fret of wonderfully detailed

deck, radar antenna reflector, other detail parts ... and even a painting mask needed to

produce the white '571' on the sides of the sail.

Also provided in the kit is a set of water-slide type decals containing the white draft

markings for the hull and upper rudder.

With this picture I'm jumping ahead a bit -- this is Aundrea's initial assembly of his kit. I

include it here to point out the use of the very detailed acid-etched deck pieces.

Provision is made in the upper GRP hull to accommodate this. A slight step is provided

atop the hull to sit this .015" thick acid-etched item atop the hull so that it sits flush.

Though the USS NAUTILUS is distinctive of lines, it is a rather boring subject to look at

if the details that are there are not exploited to the maximum -- such is the case with the

deck: safety-track, slotted wooden deck, deck hatches, marker buoys, cleats, torpedo

loading skid, these and more are items captured by the brass metal deck pieces. Even

a bridge deck grating is provided on the acid-etched fret.

Andreas will be making this kit commercially available. What is pictured above is what I

would consider to be a more than adequate kit: right down to pages of exploded-view,

orthographic and isometric drawings outlining not only assembly of the kit proper, but

recommendations for the fabrication and assembly of the European style internals.

A preliminary kit. What I'm presenting here is likely not the definitive version -- note that

there is no bayonet rings to accomplish the water tight radial break between forward

and after hull halves; that the hull pieces (five of them) are provided split to suit those

wishing to assemble this r/c submarine as either a wet-hull or dry-hull type; and no form

of tech-rack (as the dry-hull guys would describe the internals mounting arrangement)

or water tight cylinder (WTC) is provided. Also, there may be material changes before

the production kits hit the street. So, regard what I've pictured here as a Beta test

article, subject to change.